Paper

Forward

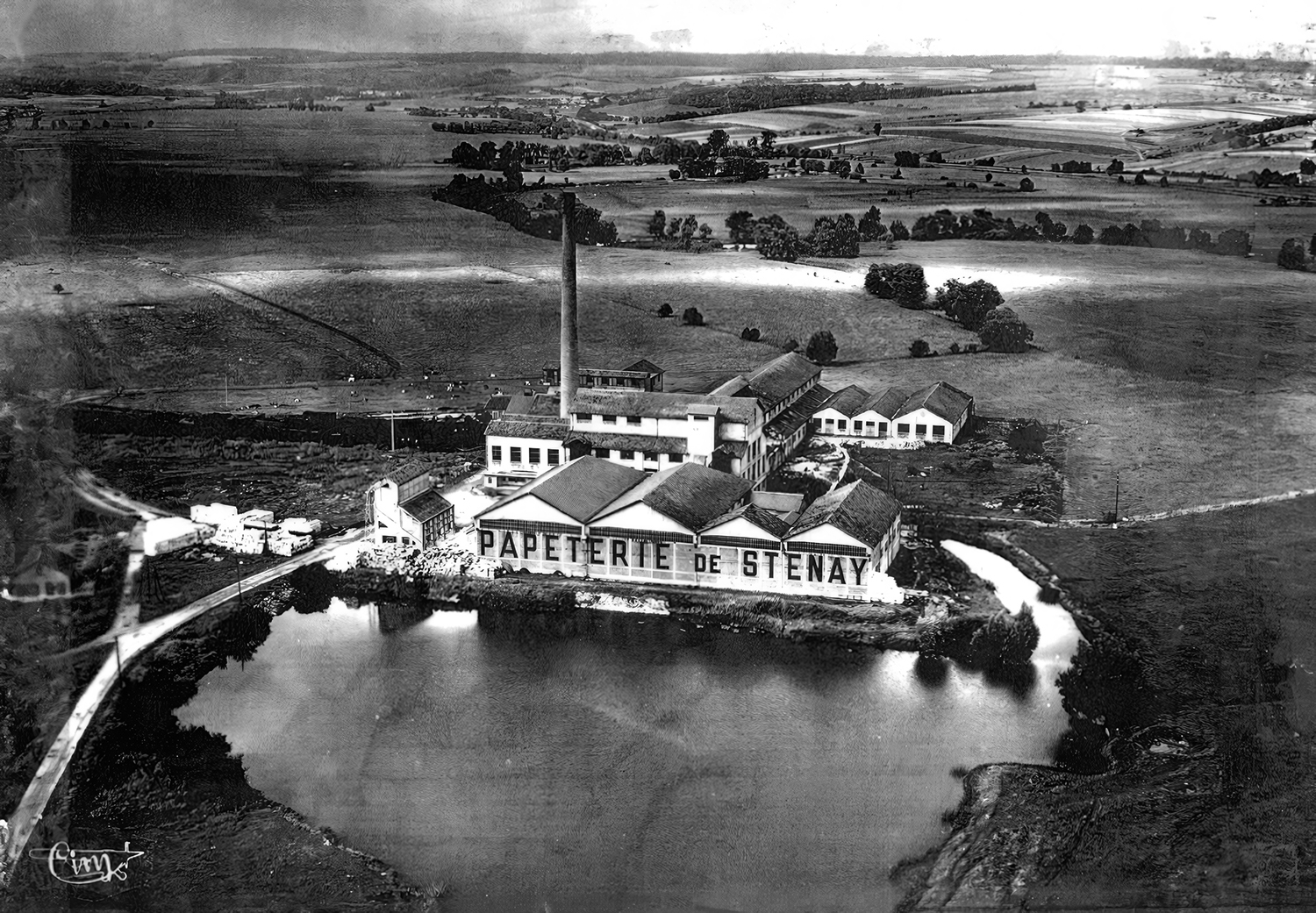

Who we are ?

Twenty years later, it went through various multinational ownerships until October 2023, when Accursia Capital took over the entire operation, including all 122 employees and the S3 paper machine. Now, the Stenay paper mill is embracing its new “family” identity under the name STENPA (Stenay Papers), thanks to Accursia Capital.

Tonnes per year production capacity

Collaborators

continents served

Production capacity

The ‘in-line’ paper machine produces one-side coated paper for special high-value applications, such as graphic papers, labels, or food packaging. With a production capacity of 70,000 tons per year, its production is based on innovative solutions using fibers, especially those sourced from sustainably managed forests (FSC/PEFC). This paper machine was commissioned in 1969 and has undergone several upgrades over the years.

The range of manufactured papers is particularly extensive, catering to various customer needs:

- Packaging Papers: Barrier, Printability, Fold Resistance, Gloss, Whiteness,

- Label Papers: Metallization,

- Special Papers: Siliconizing Capability,

- Flame-Retardant Papers: Display.

Our collaborators

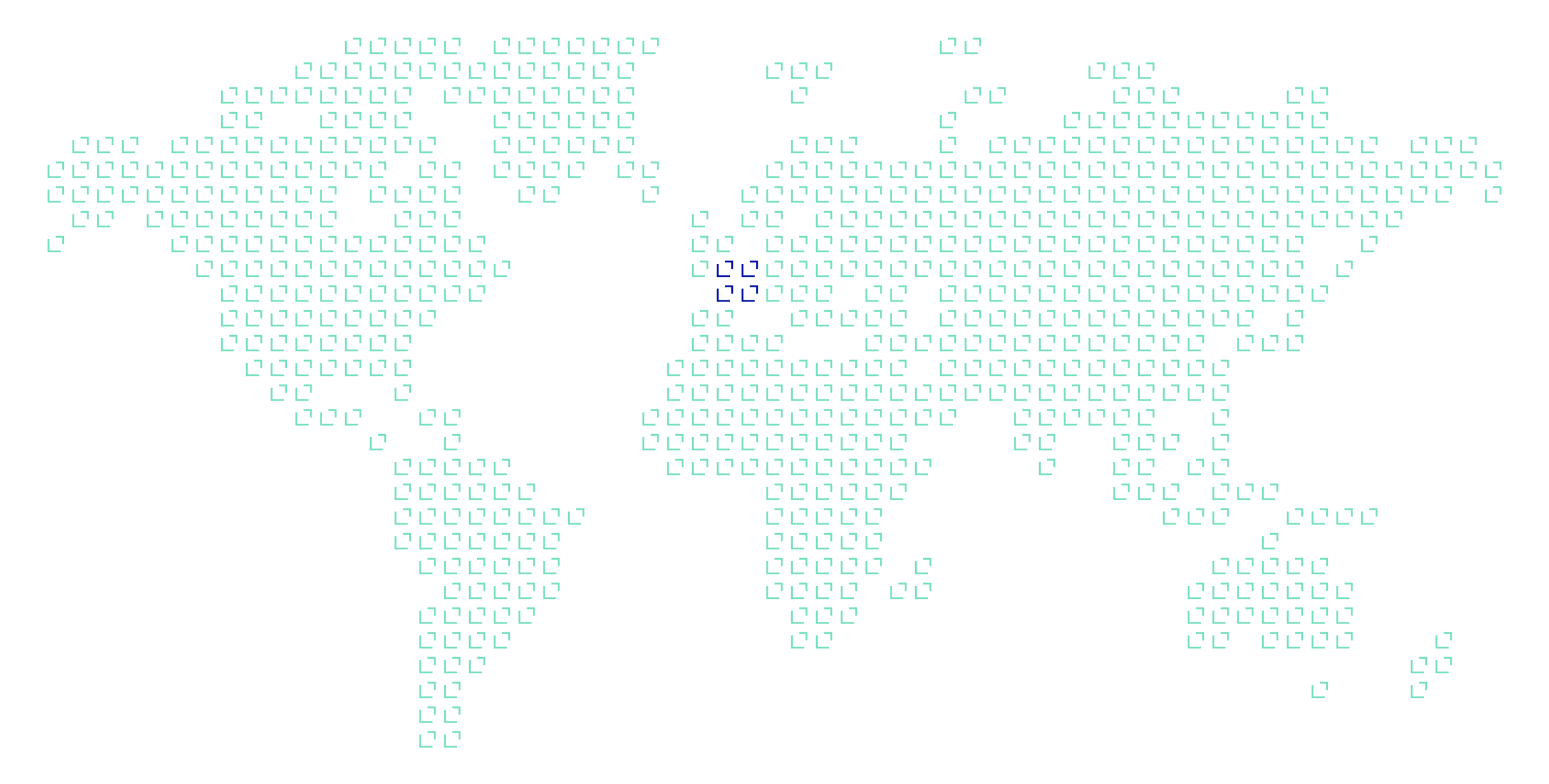

5 continents served

Our mission

All our papers are recyclable, and 100% of the fibers we use are certified. We are committed to developing increasingly eco-friendly products with great care in selecting raw materials. Furthermore, our strategic location in the heart of Europe allows us to serve the majority of our customers within a limited radius, also minimizing the carbon impact associated with transportation.

AGENT |

CONTACT PERSON |

ADDRESS |

PHONE |

|

|

GREECE |

INTERSAL |

Konstantinos Fafoutis |

20 Kandanou Str.11526 Athens Greece |

+30 210-6929734 |

faf-sal@otenet.gr |

ISRAEL |

SOLOMON |

Bilhah Solomon |

47, Yehuda Hanassi St.6939109 Tel Aviv Israel |

+972 3 6414690 |

bilhah@solomon-gm.com |

POLAND |

PAPIERKO |

Wiktoria Araszewska |

Ul. Bora Komorowskiego 53/56Bydgoszcz 85-793Poland |

+48 668301372 |

wiktoria.araszewska@gmail.com |

SOUTH AFRICA |

BORDIC |

Craig Lloyd |

ICH House57 Eastwood Road2196 Dunkeld (Johannesburg)South Africa |

craig@bordic.co.za |

|

SRI LANKA |

EASTERN AGENCIES COLOMBO (PVT) LTD |

Imaran Seneviratne |

Eastern Agencies Colombo (Pvt) Ltd4 De Fonseka PlaceColombo 5Sri Lanka |

+ 94 11 777 763196 |

imarans@sltnet.lk |

TURKEY |

ESFLEKS |

Ali Can Eser |

Suadiye Camii Sokak Muhsin Bey Apt.No: 49/14 Suadiye, 34740 IstanbulTURKEY |

+90 (216) 360 47 19 |

aeser@esfleks.com |

MIDDLE EAST |

PAPIMPEX |

Nareg Keucheyan |

1 place des charmillesPO Box 4801211 Geneve 13Switzerland |

+41 223455800 |

ngk@papimpex.com |